Developing Our 2021 Power Unit

We kicked off 2021 with pole position and an oh-so-close second place in the Bahrain Grand Prix, before arriving in Imola and seeing Max take a solid win on Sunday at Round 2. But beyond the results there has been plenty to be encouraged about when it comes to performance.

At the opening round, Red Bull Racing were the team to beat on Saturday and Max saw victory slip away due to track limits, but Sergio’s drive through the field, Pierre’s excellent qualifying performance and Yuki’s strong debut all pointed to a competitive power unit.

And it’s a power unit that is all-new for this year, one that came together after an immense effort from Honda’s teams in Sakura and Milton Keynes. As our head of power unit development Yasuaki Asaki explains, that came after a number of significant challenges over the past 12 months.

“The original plan was to implement this new structure PU this year in 2021,” Asaki-san explains. “But then for a variety of reasons, it was decided not to proceed with a brand new PU. However, the thinking on this really changed when Honda announced that we would be leaving the sport. I went to President Hachigo, and said to him that we would really like to implement this new structure PU for our last year in the sport. And he kindly accepted that request.

"With the green light given, our engineers got to work on trying to get everything ready for the new season. That was never going to be an easy task, given the scope of the changes being made to the power unit’s architecture.

“First of all we've changed the camshaft layout to be much more compact, and also brought its position lower down so it's closer to the ground,” Asaki-san reveals. “We’ve also had to change the valve angle. The main point of what we've changed was to improve combustion efficiency. In order to do so we had to change the valve angle and in order to do that we had to change the camshaft."

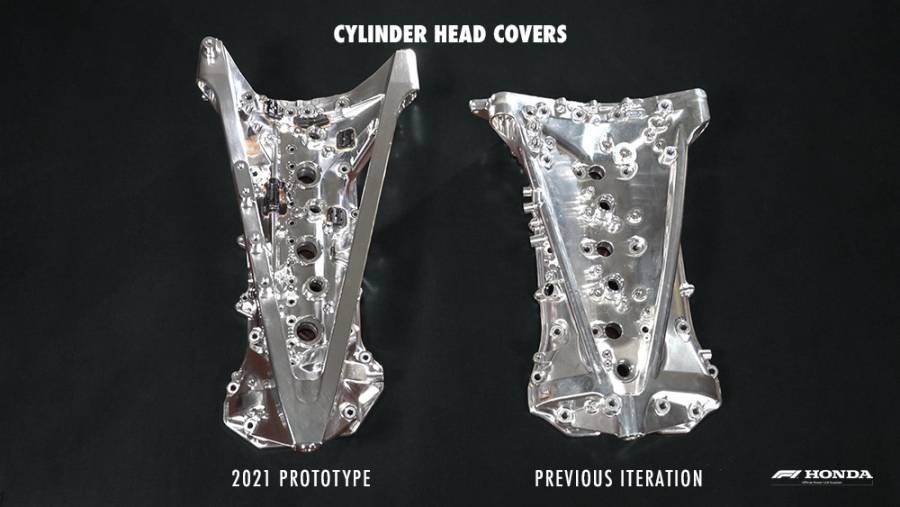

"We've also had to make the head cover lower and more compact, which means that the way that air flows over it has become a lot better. And we've also lowered the centre of gravity of the ICE.

“Another thing we changed is the bore pitch, by reducing the distance between one bore and the next, we've made the engine itself shorter, smaller.

“In the old engine straddling the transmission we also had a bank offset whereby the left bank was slightly offset from the right bank. So what we've done is reverse this offset on the new engine so that the right bank is forward and the left bank is back. I'm sure you'll appreciate this is a completely new engine. And we've been able to bring it to a point where in just six months we've taken it testing without any issues.

“Another point that we've had to think about is the fact that combustion efficiency has go better. And the camshaft output has got better. Due to the rules of physics the amount of energy that can be stored has changed and it meant that the amount of exhaust energy has decreased. So compared to the recovery that we were getting last year, what we're having to do is increase the amount of crankshaft output, and at the same time ensure that there's a good level of exhaust output, exhaust temperature as well.

“So we've had a number of different development objectives and we believe we have met them.”

Even though all of that work took place across a very condensed six-month period and required a focus on reliability as well, Asaki-san says his team were able to ensure all of the significant developments were included in the new design.

“I believe that we were able to implement everything that we have to in order to compete with Mercedes. We had a lot of cooperation from Red Bull, making sure that we could get the most from this new compact engine. Until the summer we were woking on the basis that it was going to be the previous bigger engine.”

To pull off such an achievement required collaboration from different departments within the wider Honda company, as well as the power unit team leaning on its past experiences of major development challenges.

“This is the first time that we’ve gone as far as changing the structure of the PU itself. But I think the biggest challenge that we’ve had up to this point was back in the McLaren days, when we made big changes to the MGU-H, we changed the positioning of the compressor and turbine in relation to the V bank - I think the biggest challenges were back then.

"You may be aware that a part of what helped us solve those problems back then was the cooperation with Honda Jet. As I mentioned Honda Motor has helped us with various different points, but one of the points I’d like to mention is a cylinder sleeve plating, produced by our plant in Kumamoto - it’s called the Kumamoto plating. The Kumamoto plant is actually a motorbike factory, but within Honda there’s a substantial amount of collaboration between the two-wheel production and four-wheel production areas."

In some ways, it seems like a huge undertaking given the fact that this year is Honda’s last as an official power unit supplier in F1. But Asaki-san says the efforts of the engineers was worth it both from the desire to show our capabilities, and also to simply be as competitive as possible across what is a record-breaking 23-race season.

“I had acknowledged in some ways that it was an incredibly challenging target. But I think our engineers have had both the understanding that yes we’ve only got a year left but also we’ve got a full year left and we have to do something with that time, and they’ve worked hard during the time that we have had.”

All of the work off-track went unseen over the past six months, but the competitiveness at the start of this season is the first sign of what has been achieved from a performance point of view. Now the challenge is to try and turn that into the best possible results on track.