Exclusive Interview: Hiroyuki Seki on the Suzuka 8 Hours

The Truth Behind HRC's 3rd Consecutive Win at Suzuka 8 Hours: Machine Edition — 2024 Model CBR1000RR-R SP

How Was the 2024 Suzuka 8 Hours CBR1000RR-R SP Developed? Insights from Chief Engineer Hiroyuki Seki

The motorcycles used in EWC (Endurance World Championship), All Japan JSB1000, and SBK (Superbike World Championship) are superbikes based on production models. The main frame essentially remains standard (reinforcement allowed), and engine modifications are largely restricted except for cylinder heads, cams, and transmission ratios. Therefore, the basic performance and characteristics of the homologated base models tend to be strongly reflected in their racing versions.

The Honda CBR1000RR-R debuted in 2020, received minor updates in 2022, and underwent a full model change in 2024. HRC has the advantage of being able to spend a full year developing their race machine. This is possible because Team HRC does not compete in other rounds like the Bol d'Or 24 Hours. Their CBR1000RR-R for the 8 Hours is essentially a machine specialised for the Suzuka 8 Hours.

“However, speaking of last year, 2024, we haven't been able to conduct our usual development process. Since this was a full model change year for the base machine, we had to prioritise developing the World Superbike (SBK) machine while simultaneously working on the Suzuka 8 Hours version” said Hiroyuki Seki, LPL (Large Project Leader) for the Suzuka 8 Hours CBR1000RR-R Development.

While they haven't achieved the desired results in World Superbike (SBK), they've won three consecutive victories at the Suzuka 8 Hours using the same base machine. What accounts for this difference?

“When we returned to SBK after a gap of more than a decade (in 2020), tyre technology had evolved during our absence, and we're still in the process of learning various aspects" continues Seki. "In motorsport, regaining competitiveness after a prolonged break is a significant challenge. Our return to the Suzuka 8 Hours in 2018 also posed considerable difficulties. Moreover, the timing of our SBK comeback coincided with the COVID-19 pandemic, which hindered Japanese staff from traveling freely to Europe, significantly impacting development.

“That said, we are gradually gaining a better grasp of the nuances in SBK, so please look forward to future improvements. For the Suzuka 8 Hours, Honda benefited from the expertise of veteran staff who were active during Honda’s peak era at Suzuka. This ensured smooth generational transitions and effective knowledge transfer. Additionally, while SBK uses Pirelli tyres, the Suzuka 8 Hours utilises Bridgestone tyres. Honda has extensive experience with Bridgestone, which is another major factor.”

The high rigidity of Bridgestone tyres, combined with Suzuka’s high-grip surface, and the ability to adapt factory machines to these conditions, undeniably contribute to Honda’s strength at the Suzuka 8 Hours. On the other hand, for the comparatively more pliant Pirelli tires, further fine-tuning is needed to compete effectively at the elite SBK level.

Reducing peak power, enhancing low-to-mid-speed performance

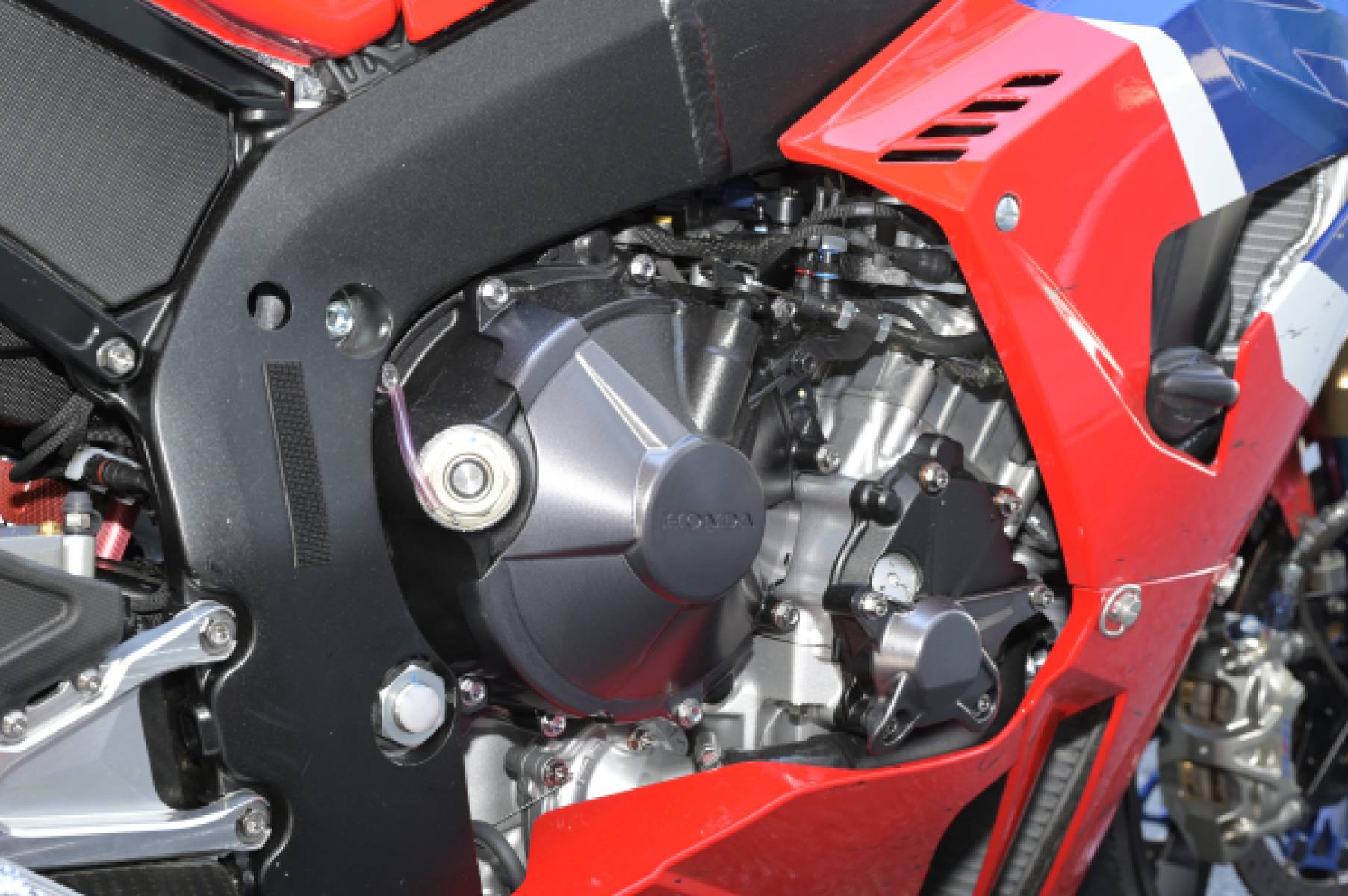

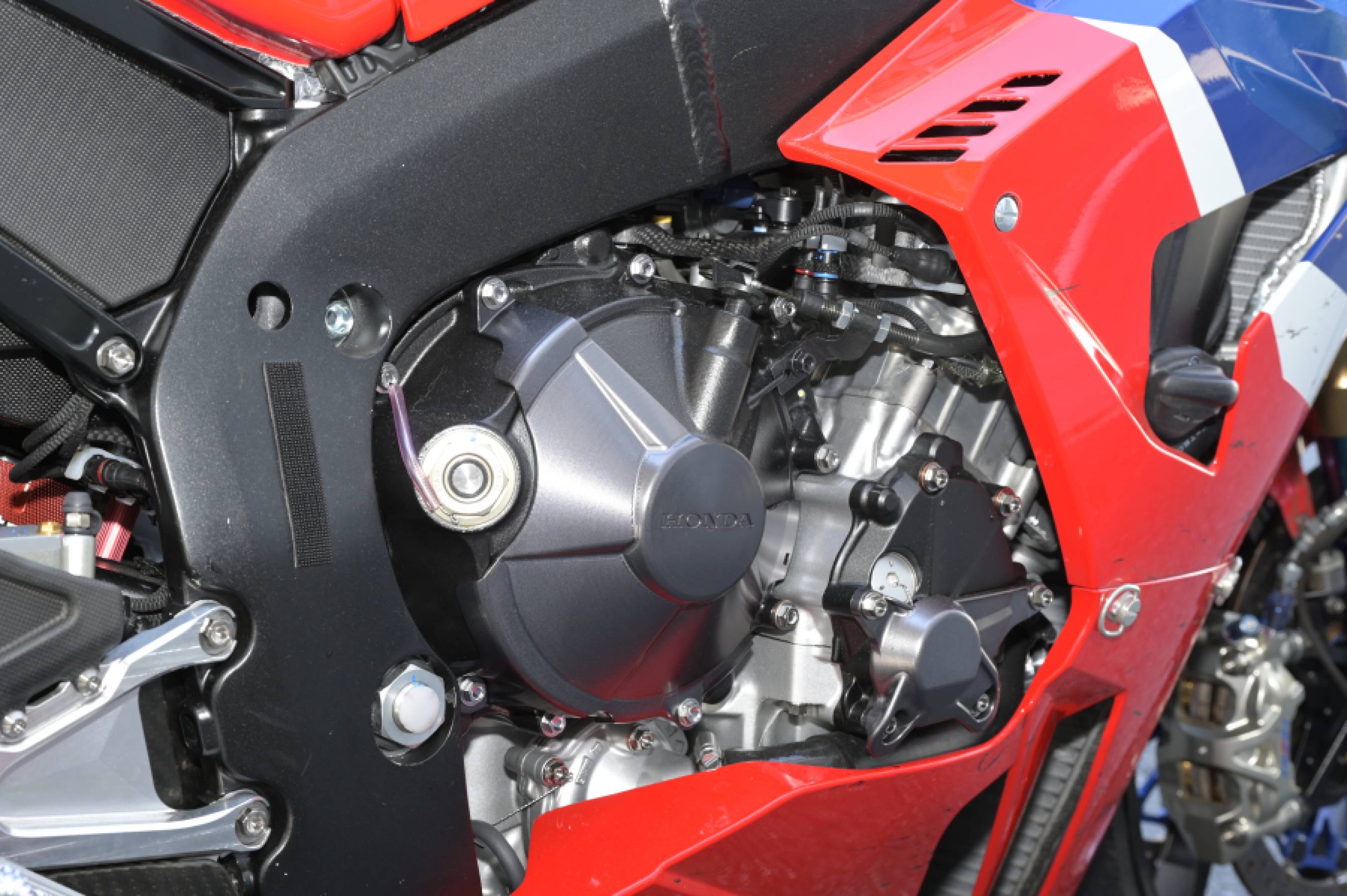

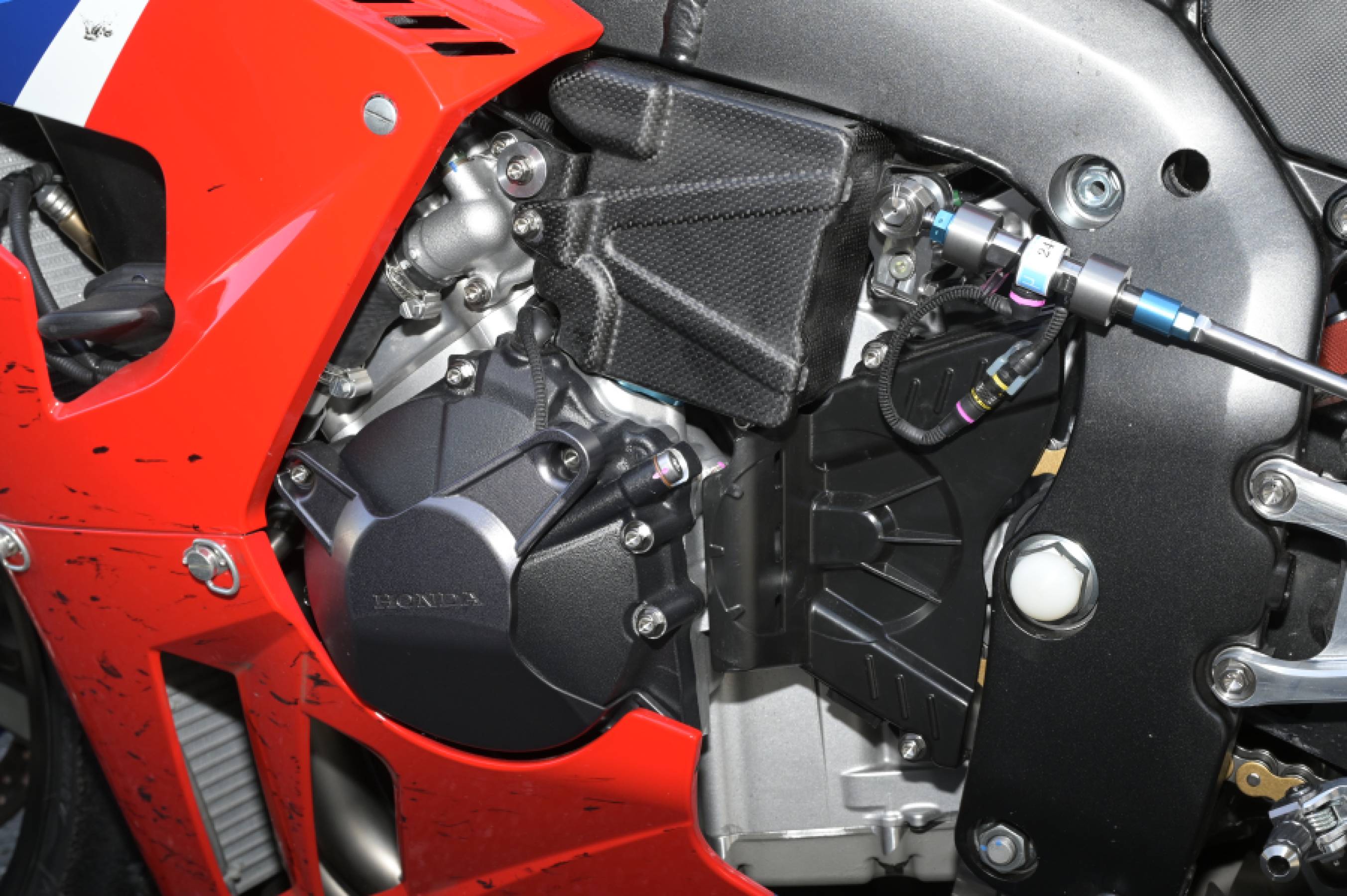

The 2024 CBR1000RR-R SP has been designed with a focus on low- and mid-range performance in its engine, while its chassis enhances cornering capabilities.

"For the HRC factory machine, the peak power output has been reduced compared to last year's model (2023 8-Hour specification), with that power being redistributed to the low-to-mid range. At Suzuka, utilising effective torque in the low-to-mid range allows for quicker acceleration to top speed, resulting in faster lap times. This characteristic is most noticeable in the section from the exit of Spoon Curve through to the back straight. The bike smoothly builds speed out of the corner, reaching its top speed earlier in the straight."

On Suzuka's back straight, top speed is reached before the 130R corner. Having excessive power that causes wheelies in 5th and 6th gear at top speeds - like the Ducati from the 990cc MotoGP era - is pointless if it doesn't translate to faster lap times. This is why the 2024 CBR prioritised low-to-mid range power, even at the expense of peak power.

"When you adjust valve timing to emphasise low-to-mid range performance, peak power inevitably drops... But in racing, it's more advantageous to increase usable, effective torque rather than focus on peak power."

For example, would it be unfeasible to maintain peak power output and use electronic control systems, such as traction control, to regulate power delivery when needed?

"The inherent characteristics of the engine itself are indeed what matter most. When you consider changes in track conditions and tyre grip, as well as the long duration of an endurance race, it's better to achieve grip through the engine's natural characteristics rather than electronic controls (like traction control). This also makes it easier for riders to control the bike.

"The cams are HRC specials. We're not doing anything particularly unusual - instead, we're focusing on how to bring out the inherent characteristics of the 2024 model. We've increased the low-to-mid range torque even more compared to the works specification up to the 2022 model. With the 2024 model, we've made it more manageable to ride. After all, the base 2024 model was designed to achieve a balance between ease of handling on public roads and on the circuit."

With the tuning that maximizes these base machine characteristics, all three riders (Takumi Takahashi, Johann Zarco, and Teppei Nagoe) could consistently achieve race average lap times of 2 min 7s to 2 min 8s. These times allowed them to complete 27-28 laps per stint.

"Our machine development focuses on allowing all three riders to maintain high speeds while minimising their physical fatigue."

In the final, all three riders consistently achieved the target lap times in the 2 min 8s range. Another factor contributing to its ease of handling and speed is the transmission. The transmission ratios approved by the FIM are limited to three ratios per manufacturer per season: standard and two additional ratios.

"For Honda, the 2024 model (available in STD and SP variants) comes with three transmission ratios. The 2024 model features a modified primary reduction ratio (changed from the previous 1.630 to the new 1.687). When this primary ratio was reviewed for the power characteristics as a factory machine, the transmission ratio that is being sold as part of the 2024 HRC kit turned out to be the optimal ratio for maximising performance at Suzuka."

"Thus, even the factory machines are using the same transmission ratio as the one being sold in the kit. Since three ratios can be registered for the CBR, one additional ratio can be added for the EWC 24-hour races, and for Honda's 2024 model, three ratios are registered: STD, HRC kit (used at the Suzuka 8 Hours), and one for the EWC 24-hour races."

One of the 8 Hours riders, Johann Zarco, said this: “Yamaha is sliding at the final corner. We stay controlled there to maintain grip, and then we overtake them on the following straight.” True to Zarco's words, HRC's CBR overtook YART. This was a moment that highlighted the 2024 model's characteristics - its emphasis on low-to-mid-range speed and superior cornering ability. How has the chassis evolved? How is a machine with excellent cornering ability and superior agility created?

Built Below the Minimum Weight Regulations?!

The 2024 STD model's frame achieves a remarkable weight reduction of 960g compared to its predecessor (with a minimum wall thickness of 2mm). Additionally, the hanger bolts have been lightened by 140g through shortened bolt length and modified fastening structures (six engine fastening points). Furthermore, the engine itself is 720g lighter, resulting in a total weight reduction of approximately 1.8kg.

However, despite the weight reduction, it's not so straightforward because Formula EWC has a minimum weight requirement of 170kg (excluding the fuel tank and its contents - fuel and fuel pump). The minimum weight measured in pit lane during free practice and qualifying is 177kg (including the fuel tank and its contents).

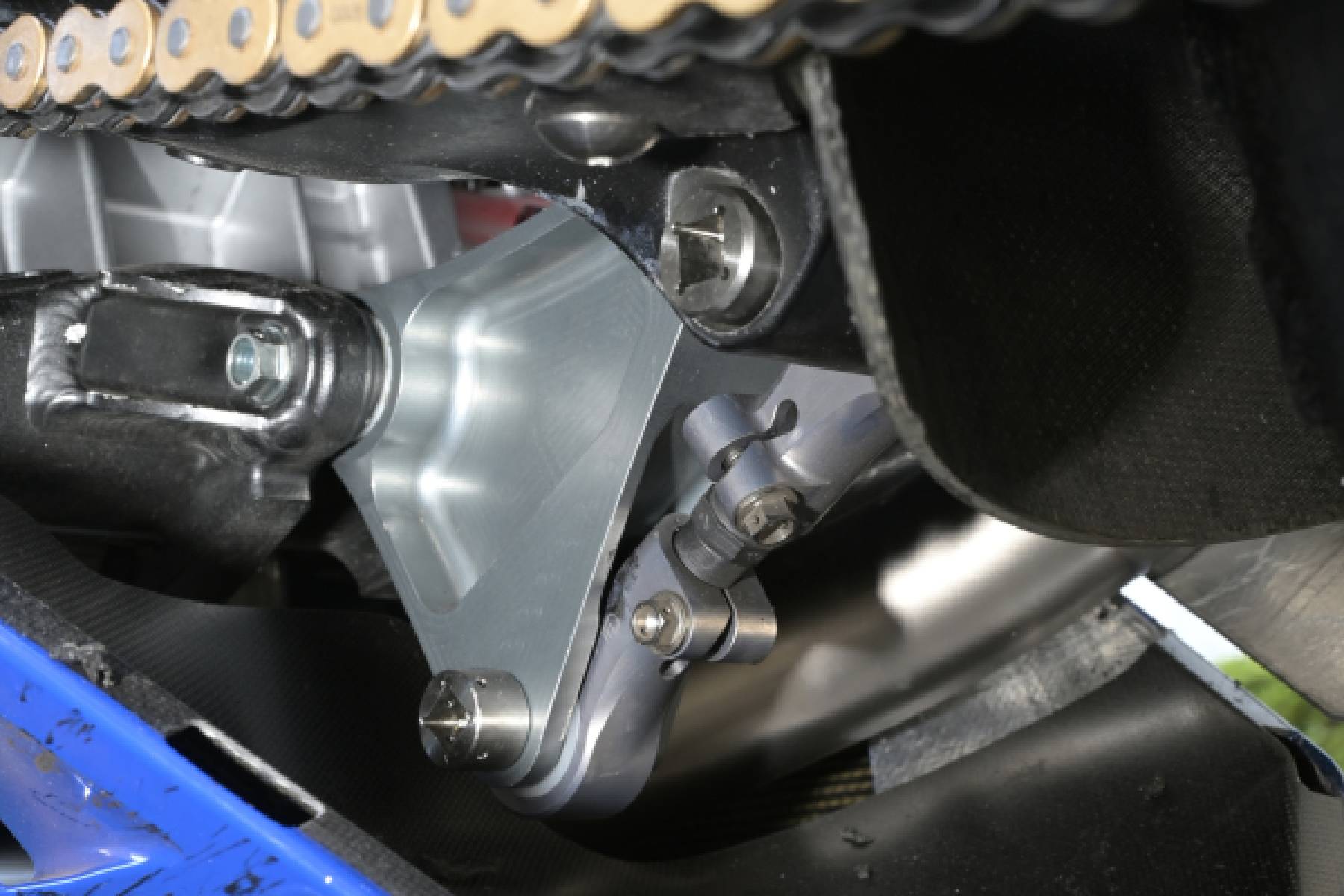

“To be honest, the completed machine is lighter than the regulation minimum weight, so we ultimately adjust it by mounting dummy weights (ballast). I cannot disclose exactly how many kilograms, but we use quite a lot. The dummy weights are typically made of stainless steel, but we also use tungsten. However, tungsten is not only expensive but also difficult to machine, so it costs more and takes more time...”

That's why stainless steel is mainly used for weights, with tungsten used only for crucial locations. The density of stainless steel is 7.7-7.9, tungsten is 19.3, and ordinary iron is 7.8. Building the machine lighter than regulations and then placing dummy weights in positions where moment of inertia is small and the centre of gravity is low can be quite effective. Moreover, the mounting points can be distributed across several locations. In this way, having a machine built lighter than required is advantageous because dummy weights can be strategically utilised.

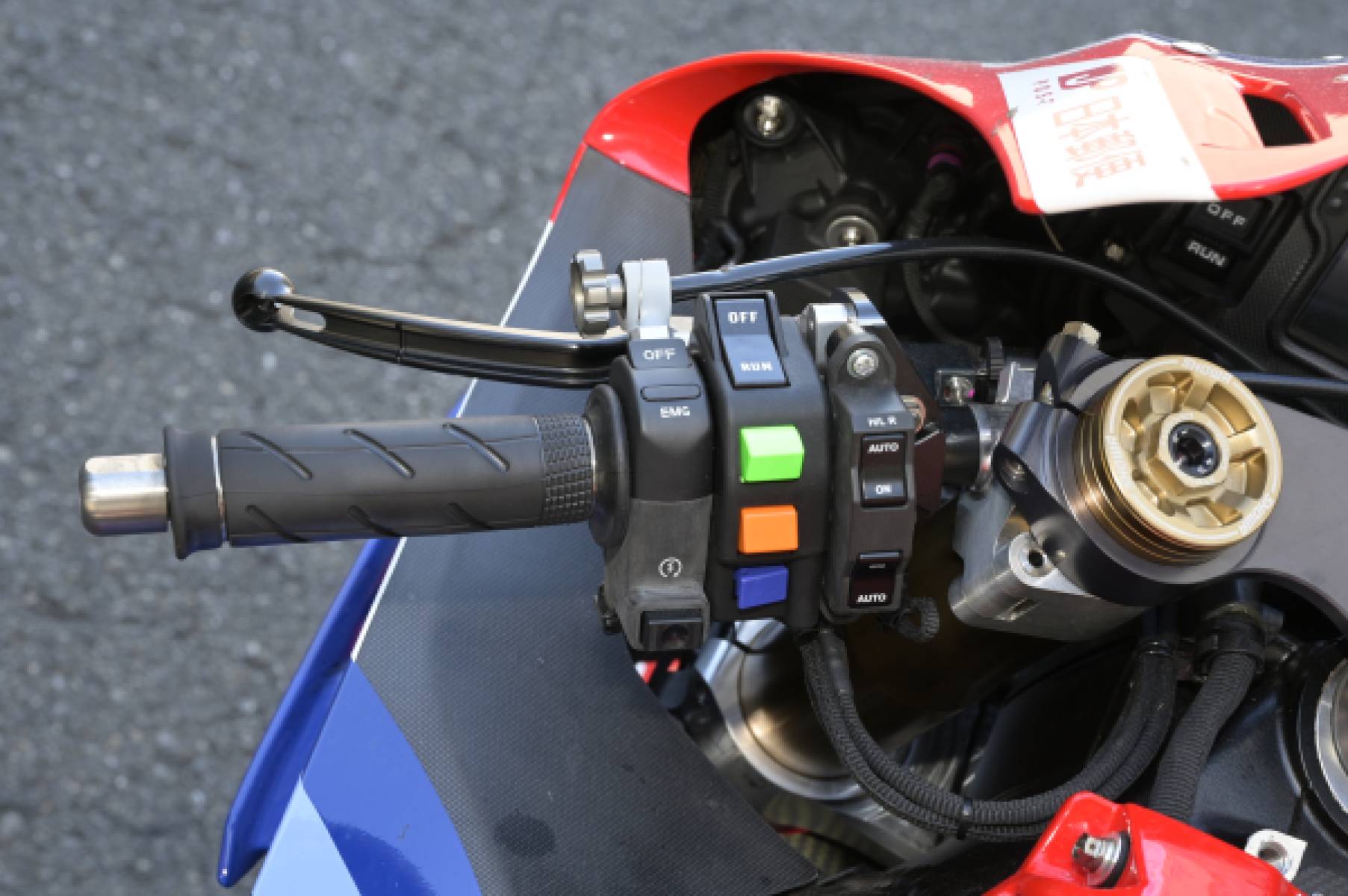

"The weights are mounted at points relatively close to the center of gravity on the lower cross section of the frame (the part that connects the left and right sides below the swingarm pivot). As regulations require fastening with at least two M8 (8mm) bolts, we mount them securely. During technical inspection, we must declare where the dummy weights are mounted, so there's no way to hide them (laughs).

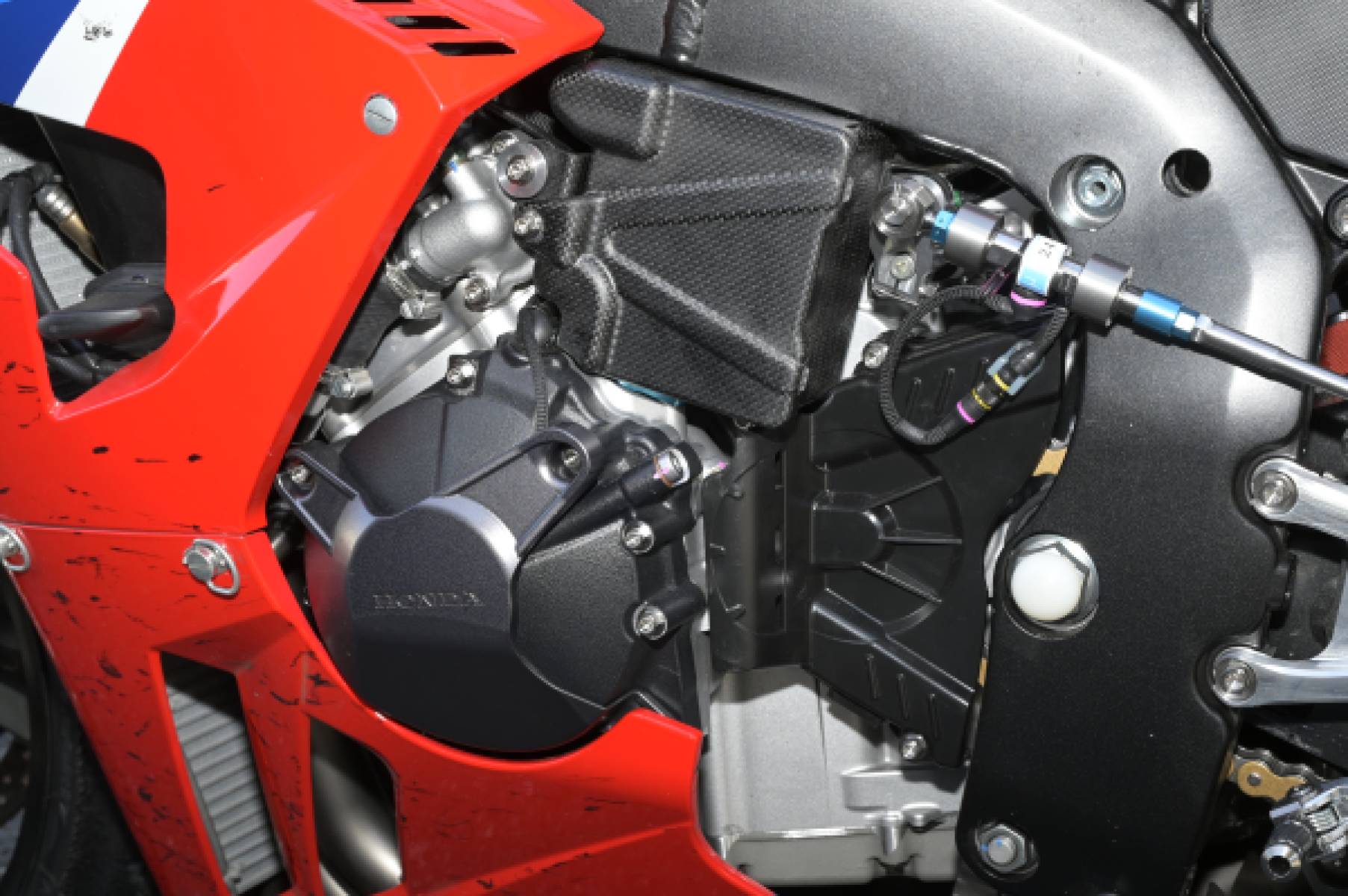

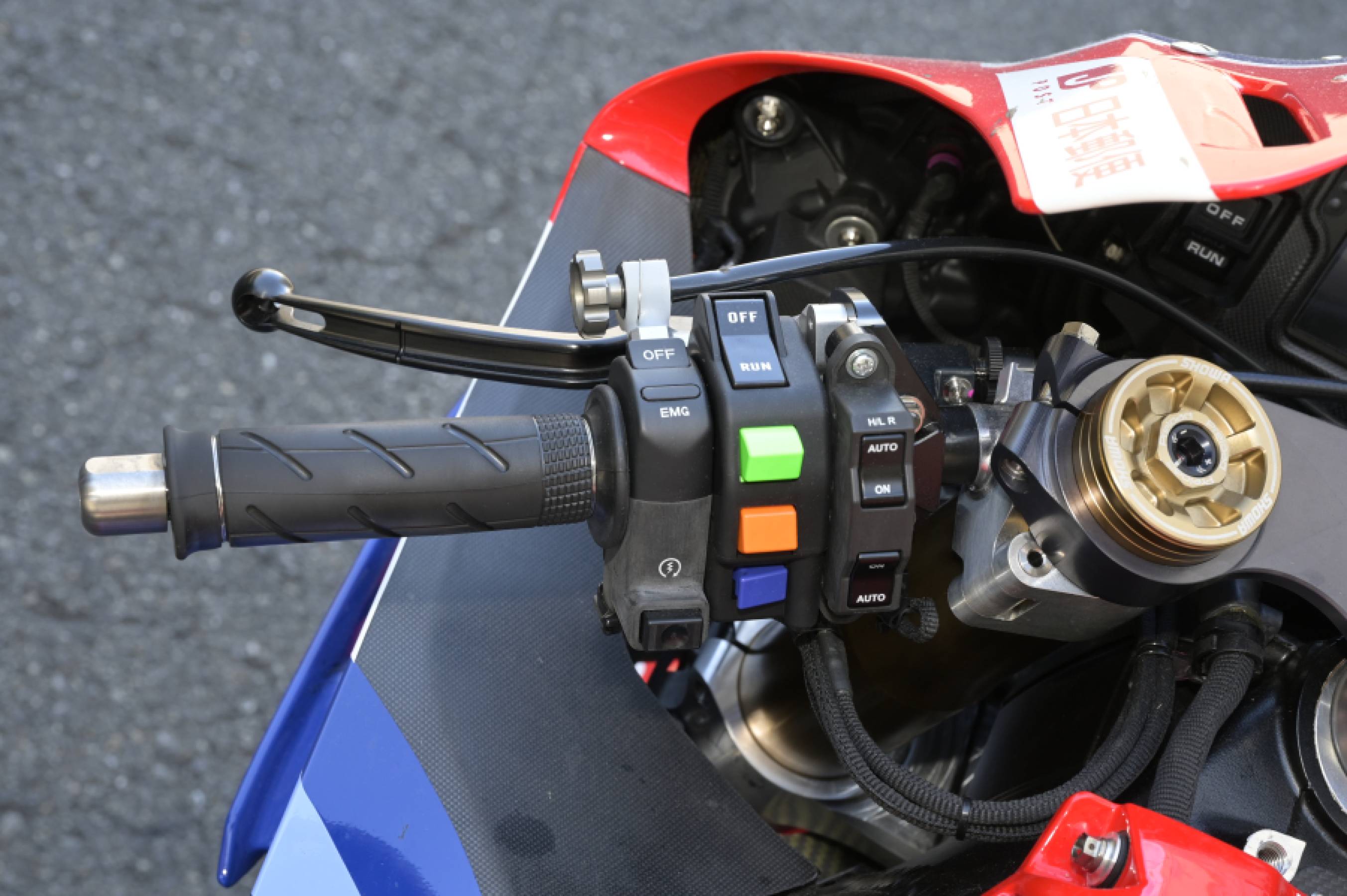

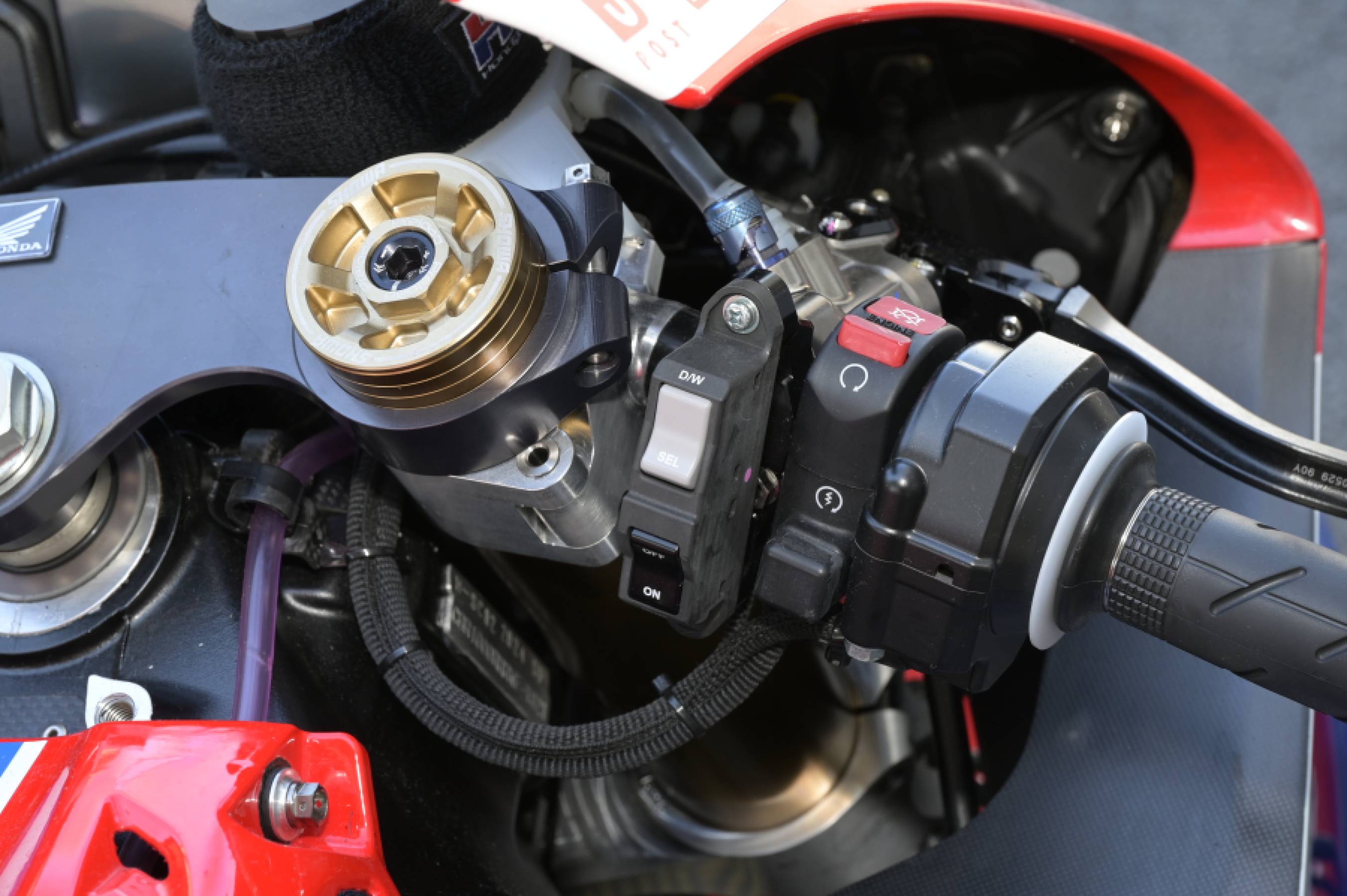

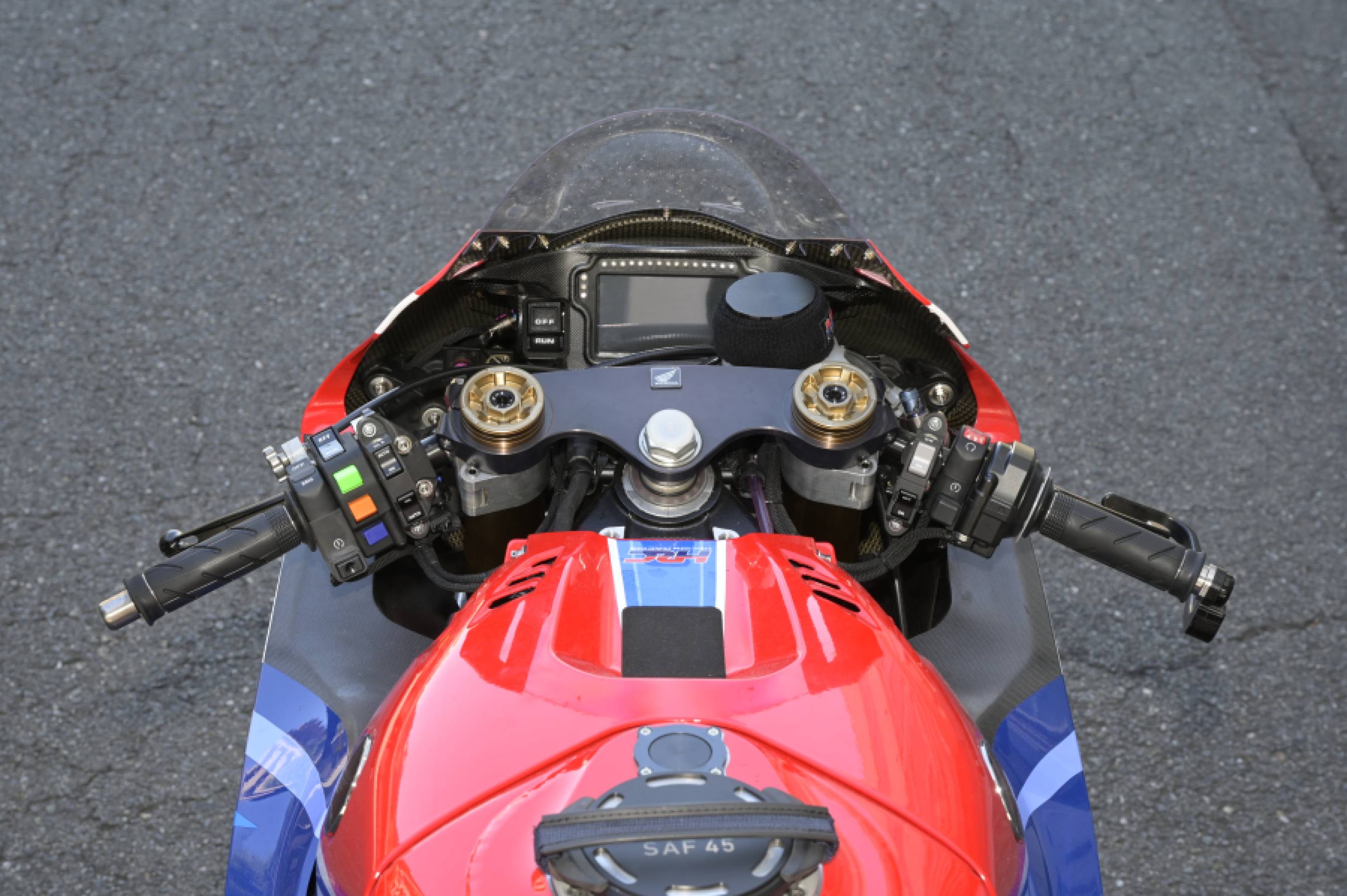

"Dynamic performance is determined by physical specifications. What we do is decide where to place the centre of gravity, how to minimise the moment of inertia, and how to make the machine lighter. Placement of the centre of gravity primarily depends on the positioning of major components. This means deciding where to place the ECU and battery, and where to route the harness (wiring). Since the ECU weighs about 1kg, we place it under the fuel tank. The battery is located behind the cylinder on the engine's left side and is covered with CFRP.

"To minimise the moment of inertia, the key is to avoid placing heavy objects far from the centre of gravity. And since the moment of inertia can be reduced simply by making the overall weight lighter, we are thoroughly committed to weight reduction."

The battery is the same Eliiy Power lithium iron phosphate battery used in the standard CBR. And the ECU is made by Marelli, the same as in MotoGP.

"In EWC, while we have the freedom to choose any ECU, we use one made by Marelli. Since Marelli ECUs are also used in MotoGP, they are easier for Honda to work with (though the software is Honda's original). However, it's different from the MotoGP version. We select the ECU based on the optimal balance of required functions and performance."

The 2024 Model Prioritises Cornering Performance

While achieving weight reduction, the 2024 model frame has reduced rigidity compared to its predecessor, with -17% lateral rigidity and -15% torsional rigidity. The aim is to improve cornering ability by increasing flexibility. This is likely also in response to the (relatively low rigidity) Pirelli tires used in SBK.

"While media reports say, 'the 8 Hours spec HRC factory machine turns well,' we don't necessarily think it turns that well, and believe we need to improve its cornering ability further. Although it's based on the STD frame, reinforcement is possible."

In Superbike racing generally, while frames can be reinforced by adding gussets and tubes, removing any original frame components is prohibited. Of course we do reinforce the frame, and it's specifically designed for the 8 Hours with different specifications from the frames used by Takumi Takahashi and other riders in the All Japan series, adapted to match the rigidity of Bridgestone tyres. Incidentally, HRC factory does not participate in the All Japan series, so CBR teams there typically race with HRC kit bikes.

Additionally in Formula EWC, the steering head position can be adjusted by ±6mm forward or backward by inserting bearing seats with bearings, and the swingarm pivot position can be adjusted by ±5mm forward or backward. All necessary welding and machining work for these adjustments is permitted.

“For the steering head, we make very slight adjustments to the caster angle. For the swingarm pivot, we insert collars on the inside and use their eccentricity to raise the pivot position slightly (in the direction that adds swingarm drop angle). We don't change the pivot’s forward/backward position. The swingarm length is neither longer nor shorter than the STD.”

In other words, the HRC factory's 8 Hours specification has a slightly modified caster angle from the STD's 24°07', and the wheelbase remains almost unchanged at 1,455mm. While the swingarm is similar to that of the HRC kit bike, this is a factory special (with different rigidity to match Bridgetone tyres).

“The swingarm is made through pressing rather than machining from solid. If you ask whether machining would dramatically improve performance... it doesn't make much difference. In fact, machining parts that thin can cause warping, and then correcting that warping raises issues with precision control and extra work...”

While machining from solid allows freedom in choosing shapes, it becomes extremely expensive. If the shape is more or less determined, welded pressed materials are sufficient. A distinctive feature of the swingarm's shape is its increased width due to the large offset of the brake disc. While this makes tyre changes easier, it's disadvantageous for rigidity. This shape has actually been in use for many years.

“After all, in the Suzuka 8 Hours race, pit work efficiency is crucial” concludes Seki.

Losing one second in pit work creates a significant burden on riders trying to make up that time on the track. Moreover, with 7-8 pit stops, this amounts to 7-8 seconds of lost time. In the Suzuka 8 Hours, such a time loss can determine the outcome of the race.

“Though we achieved three consecutive wins in the 8 Hours, there were moments when we thought 'if that had happened differently, we would have lost.' This year, for instance, when we thought the SC (Safety Car) would come in and eliminate our lead, it only stayed out for a moment... And even with a 40-second lead, after a penalty at the end, the margin was reduced to about 8 seconds. In the Suzuka 8 Hours, you truly never know what might happen.”

“With the 2024 HRC factory machine, there are still many things left to be done. We believe there's still room for improvement in both the engine and chassis.”

Written by: Tomoya Ishibashi Photography by: Naoyuki Shibata Edited by: Shigeki Ueno

Honda CBR1000RR-R FIREBLADE / SP Official Website

https://www.honda.co.jp/CBR1000RRR/